2026 Top Rubber Pump Impeller Trends and Insights?

The Rubber Pump Impeller industry is experiencing significant transformations as we approach 2026. According to a recent market analysis by Global Industry Analysts, the demand for rubber pump impellers is expected to grow by over 4% annually. This growth is driven by advancements in materials and manufacturing processes, making rubber pump impellers more efficient and durable.

Industry expert Dr. Alice Thompson, a leading researcher in fluid dynamics, emphasizes the importance of innovation. She states, "The future of Rubber Pump Impeller technology lies in enhancing performance while addressing environmental concerns." As companies strive for sustainability, integrating eco-friendly materials into designs becomes crucial. However, challenges remain, including the need for improved supply chains and addressing cost-related issues.

Fluctuations in raw material prices impact production. Moreover, the competition from alternative materials like plastics poses a threat. Understanding these trends is vital for stakeholders aiming to navigate the shifting market landscape. The insights gathered will shape strategic decisions moving forward in the Rubber Pump Impeller sector.

2026 Predictions for Rubber Pump Impeller Market Dynamics

The rubber pump impeller market is evolving rapidly. By 2026, the market is projected to reach approximately $1.5 billion, according to recent industry reports. This growth mirrors increasing demand in various sectors, including water treatment and industrial applications.

Market dynamics are shifting. A significant trend is the move towards eco-friendly materials. Sustainability is now a priority for manufacturers. Environmental regulations play a crucial role. They are motivating companies to innovate. The adoption of advanced rubber compounds can reduce environmental impact while enhancing performance.

Challenges persist in this evolving landscape. Some manufacturers face high raw material costs. This can restrict production capabilities. Additionally, the durability of rubber impellers remains a concern. In some applications, wear and tear can lead to failures. This drives the need for ongoing research and development. Insights from industry leaders suggest that collaborative efforts will be vital. They stress the importance of addressing these challenges efficiently.

Key Trends Influencing Rubber Pump Impeller Design Innovations

The design of rubber pump impellers is undergoing significant changes. Environmentally friendly materials are gaining traction. This shift responds to increased demand for sustainable solutions. Manufacturers are exploring bio-based rubbers. This could reduce the carbon footprint of pump production.

Another trend is the focus on durability and efficiency. Impellers need to withstand harsh conditions. That includes high pressures and abrasive materials. Recent innovations aim to enhance wear resistance. However, achieving this can be challenging. Balancing performance and cost is often a tightrope walk.

Customization is also vital in modern designs. Customers want tailored solutions for specific applications. This demands more flexible manufacturing processes. It can complicate production lines. Yet, it opens new opportunities for innovation. The industry is in a state of continuous evolution. Embracing these changes requires reflection and adaptation. There’s a need for ongoing research to shape the future.

Impact of Material Science Advances on Rubber Pump Impellers

The evolution of material science significantly impacts rubber pump impellers. Recent research indicates that advanced polymers enhance flexibility and durability. For instance, studies show that new formulations can improve wear resistance by up to 30%. This is crucial, especially in demanding industrial settings.

Innovative materials can also boost the performance of rubber pump impellers under various conditions. High-performance elastomers withstand harsh chemicals and extreme temperatures. In some applications, they have shown to operate effectively at temperatures up to 150°C. However, the trade-off can be increased costs and complexity in manufacturing processes.

Another key trend is the emphasis on sustainability. Eco-friendly rubber compounds have emerged as a viable alternative. While their performance is improving, challenges remain. The consistency of these new materials can vary widely. Therefore, industries must remain vigilant in testing and quality assurance.

Sustainability Practices in Rubber Pump Impeller Manufacturing

Sustainability in rubber pump impeller manufacturing is becoming increasingly crucial. Industry reports indicate that around 30% of manufacturers adopted sustainable practices in the past year. This shift includes using eco-friendly materials and optimizing processes to reduce waste. Many companies are seeking to decrease their carbon footprints while maintaining product quality.

One noteworthy trend is the shift towards recyclable and biodegradable rubber compounds. Conventional rubber lacks these qualities, resulting in significant landfill waste. In 2023, eco-friendly rubber materials saw a 15% increase in utilization among top manufacturers. This change promises to enhance sustainability while meeting performance needs.

However, not all manufacturers are on board. Some still rely on traditional methods that contribute to environmental degradation. Concerns about cost and performance persist, leading to hesitations in adopting sustainable materials. The industry must confront these challenges head-on to progress toward a more sustainable future. Recycling programs and education on sustainable practices are vital to overcome these hurdles.

Emerging Technologies and Their Role in Rubber Pump Impeller Efficiency

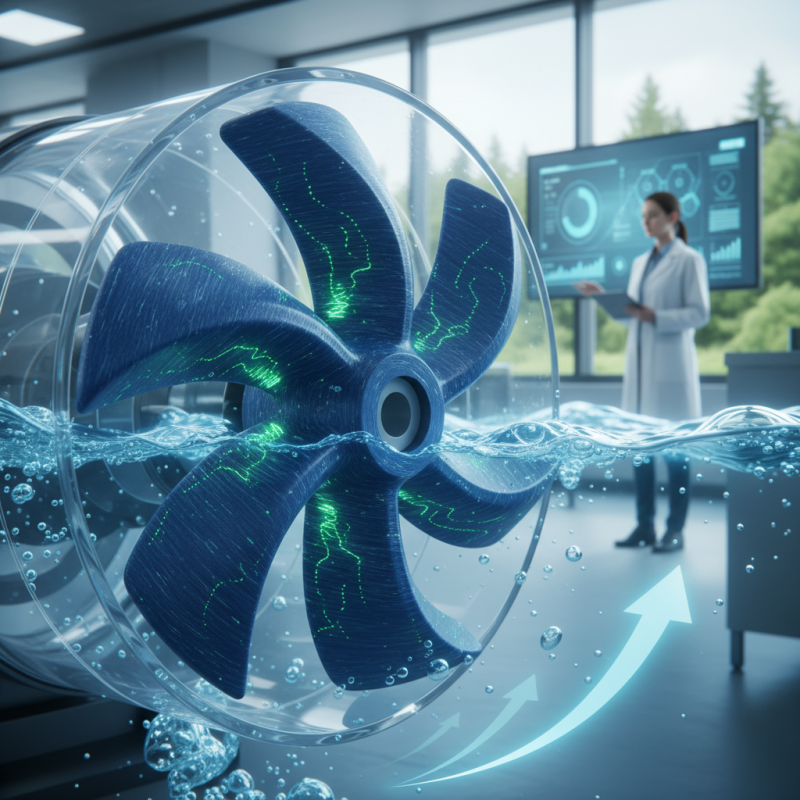

The rubber pump impeller sector is evolving rapidly. Emerging technologies are key to enhancing efficiency. Innovations such as 3D printing are transforming production methods. They allow for complex designs that traditional methods can't achieve. This precision leads to better performance in various applications.

New materials are also making a significant impact. Advanced rubber compounds offer greater durability and resistance to wear. These materials can improve the lifespan of impellers, but they come at a cost. Not all manufacturers can afford to invest in these new technologies. Some still rely on outdated methods, leading to inefficiencies in operation.

The integration of smart technology is another promising trend. Sensors can monitor performance in real-time. This information helps in making informed adjustments. However, the transition to smart systems can be challenging. Many companies are hesitant to make the leap due to complexity and cost. Balancing innovation with practicality remains a hurdle. There’s a need for ongoing assessment of these technological impacts.

Article Source:

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org