2026 Top Wire Mesh Weaving Machine Innovations and Trends?

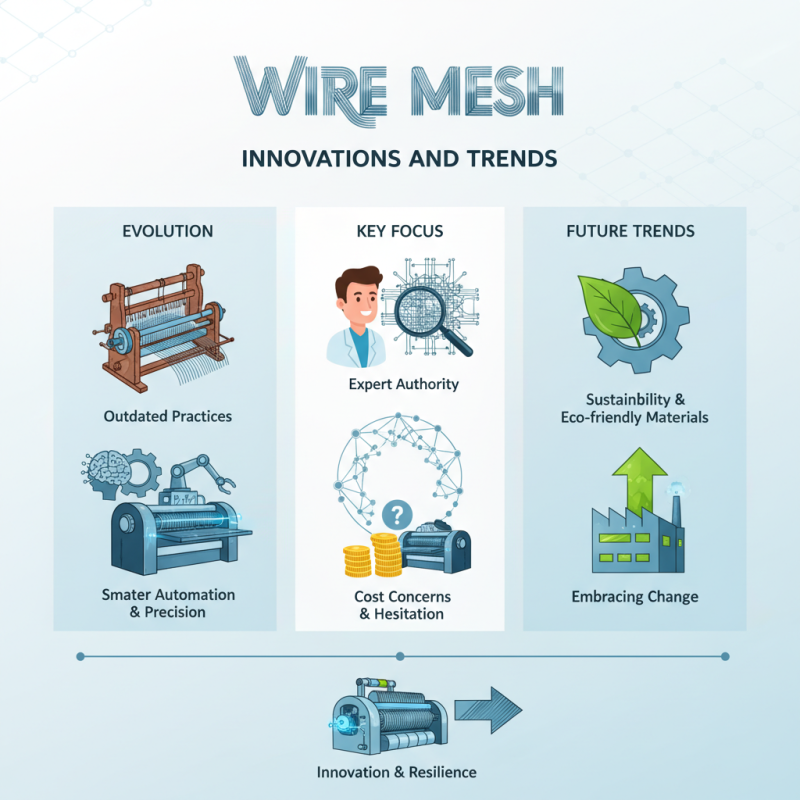

The wire mesh weaving machine industry is evolving rapidly. Innovations are reshaping how manufacturers approach design and production. Experts like Dr. John Smith, a leading authority in the field, emphasize the importance of these advancements. He once stated, “Adaptability is key in the wire mesh weaving machine sector.”

In recent years, technology has introduced smarter automation and enhanced precision. Companies are now integrating artificial intelligence into their machines. This shift not only boosts efficiency but also improves product quality. However, some sectors still struggle with outdated practices. Many companies hesitate to invest in new technology due to cost concerns.

As we look towards 2026, trends indicate a growing focus on sustainability. Eco-friendly materials are becoming more prevalent in the production process. Industry leaders are encouraged to reassess their methods and embrace change. The future of wire mesh weaving machines lies in innovation and resilience.

Top Innovations in Wire Mesh Weaving Machines for 2026

In 2026, the wire mesh weaving industry is set to experience exciting innovations. Advanced automation will enhance efficiency. Machines will require less manual intervention, leading to improved productivity. This is crucial for manufacturers aiming to meet high demand.

One of the most notable trends is the introduction of smart technology. IoT-enabled machines can monitor performance in real-time. This technology allows for predictive maintenance, reducing downtime. However, reliance on these systems may lead to challenges in worker adaptability.

**Tip:** Regular training sessions can help employees adjust to new technologies. Embracing innovation is important but should be balanced with practical skills development.

Additionally, sustainable materials will become more prevalent in production. Manufacturers will explore eco-friendly wire options. While this is a positive trend, sourcing such materials might not be easy. It requires a shift in traditional supply chains.

**Tip:** Research local suppliers of sustainable materials. Building strong relationships can ease the transition to greener practices.

Investing in flexible machinery is another focus. Machines that can handle diverse materials are essential. They offer versatility in production. However, equipment that adapts to all situations may have limitations in quality control.

Key Trends Shaping the Wire Mesh Industry in 2026

The wire mesh industry is evolving rapidly. As we approach 2026, several key trends will shape its future. The integration of smart technology in weaving machines is one significant trend. According to a report by MarketsandMarkets, the smart manufacturing market is expected to reach $397.9 billion by 2026, indicating a growing interest in automation. This will lead to improved efficiency and reduced labor costs.

Sustainability is another crucial factor. The demand for eco-friendly materials is on the rise. Reports suggest that 70% of customers prefer products made from recycled materials. Companies are now looking for sustainable wire mesh options. However, many still rely heavily on traditional practices. This gap signals a need for reflection in adaptation strategies.

Moreover, the customization of wire mesh products is becoming common. Clients seek specific features, which require machines capable of diverse outputs. Recent data shows that 60% of manufacturers struggle to keep up with these customization demands. This inconsistency highlights a critical area for innovation in machine design. Companies must address these challenges or risk falling behind in a competitive market.

Impact of Automation on Wire Mesh Weaving Efficiency and Quality

Automation is transforming the wire mesh weaving industry. Modern machines improve weaving efficiency significantly. These advancements can lead to higher production rates. Faster machines reduce labor costs too. However, this shift comes with challenges. Not every company can easily adopt new technology.

Quality is a key concern in automated weaving. While machines can produce consistent patterns, human oversight is still crucial. Operators must regularly check for defects. A minor glitch in programming can ruin an entire batch. This can lead to wasted resources and time.

Investment in training is essential. Workers must understand how to operate advanced equipment. They should also be prepared for troubleshooting. Striking a balance between automation and skilled labor is important. Relying solely on machines may overlook crucial craftsmanship aspects. These reflections highlight the complexity of integrating technology into traditional practices.

2026 Innovations in Wire Mesh Weaving Machines

This chart illustrates the projected key improvements in wire mesh weaving machines for 2026, highlighting the impact of automation on overall production efficiency and quality ratings.

Sustainability Practices in Wire Mesh Weaving Technologies

Sustainability is becoming essential in wire mesh weaving. As industries evolve, the focus shifts to eco-friendly technologies. These advancements aim to reduce waste and use renewable resources. New materials are emerging, such as recycled metals. This promotes a circular economy in mesh production.

Production processes are also adapting. Energy-saving machines are now more prevalent. They consume less power while maintaining productivity. However, this transition faces challenges. Some manufacturers resist changes due to costs. Additionally, different regions have varying regulations, complicating the move towards sustainability.

Investing in training for workers can improve understanding of eco-friendly practices. Educating staff on sustainable techniques can lead to better outcomes. Collaboration within the industry is vital for sharing knowledge. Growth depends on collective efforts rather than isolated initiatives. Sustainable wire mesh weaving is the future, but there's much to consider.

Market Growth: Wire Mesh Weaving Machine Demand Projections for 2026

The demand for wire mesh weaving machines is set to soar in 2026. Industries such as construction, agriculture, and automotive are driving this growth. Wire mesh is essential for fencing, filtration, and reinforcement. As these sectors expand, the need for efficient machinery will increase.

In this dynamic market, innovation is key. New machines may focus on speed and versatility. Many manufacturers are exploring automation features. These allow for reduced labor costs and improved productivity. However, not all adaptations are perfect. Some innovations might lead to increased complexity, which can hinder usability for smaller operations.

Tips: Consider investing in training for staff. Proper training ensures that new machines are utilized effectively. Another suggestion is to keep an eye on energy costs. Machines that are energy-efficient can provide long-term savings. The future looks bright, but businesses must adapt thoughtfully.

Article Source:

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org