Best Steel Scaffolding for Sale What to Consider When Buying?

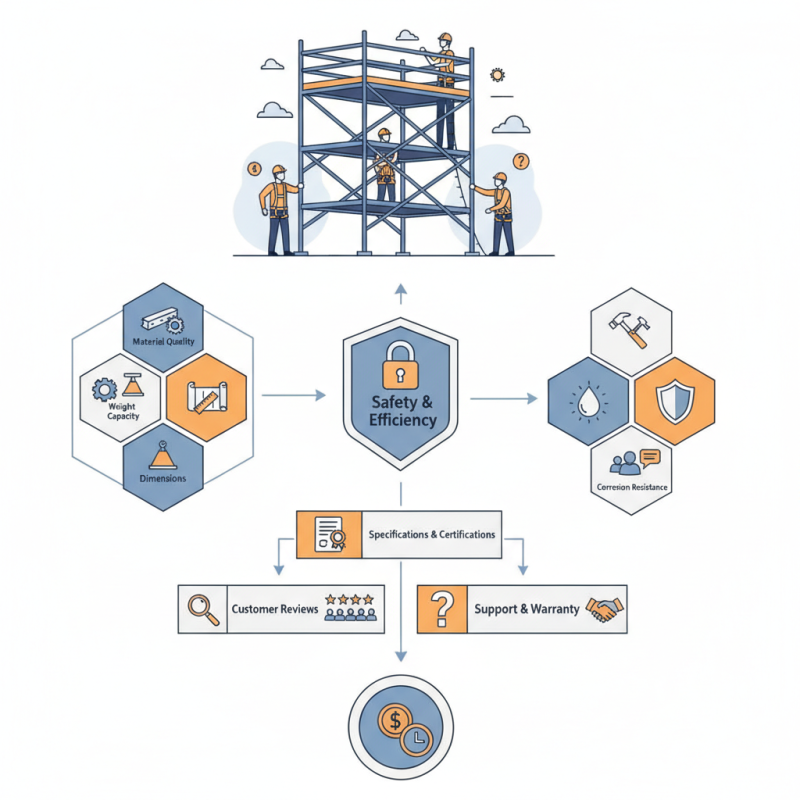

When searching for steel scaffolding for sale, it is crucial to understand the key factors influencing your choice. Buyers must consider material quality, weight capacity, and dimensions. A strong scaffolding system ensures worker safety and project efficiency.

Look for durability and corrosion resistance when selecting scaffolding. Not all scaffolding is created equal; some may not meet safety standards. It's essential to verify the specifications and certifications of the products. The right scaffolding should support the specific needs of your project, whether it's for construction, maintenance, or repair tasks.

Many buyers overlook the importance of customer reviews. Real-world experiences can reveal much about the scaffolding's performance. If a product has mixed reviews, it may be worth reflecting on its overall reliability. Additionally, consider if the seller provides adequate support and warranty options. Making informed decisions can save time and money in the long run.

Types of Steel Scaffolding Available for Purchase

When considering types of steel scaffolding for purchase, various options suit different needs. The most common types include fixed, mobile, and suspended scaffolding. Fixed scaffolding offers stability and is ideal for long-term projects. Mobile scaffolding provides flexibility, perfect for tasks requiring frequent movement. Suspended scaffolding, on the other hand, is great for accessing high areas.

Tips: Assess your project needs carefully. Not all types fit every job. Check dimensions, weight capacity, and materials. Choose lightweight options if portability is essential.

It's essential to prioritize safety features in your selection. Look for robust guardrails and non-slip platforms. However, remember that not all scaffolding designs comply with safety standards. Avoid rushing your decision. Investing time in research helps ensure you buy the right type.

Consider the assembly and disassembly process. Some scaffolding types require specific tools, while others do not. Ease of setup can save valuable project time. Sometimes, complicated designs lead to mistakes. Prioritize user-friendly structures, as efficiency is key.

Key Features to Look for in Steel Scaffolding

When choosing steel scaffolding, there are key features to consider that can significantly impact your project. First, load capacity is crucial. The scaffolding should support the maximum weight your workers and materials will impose. Research indicates that scaffolding must typically handle at least 4 times the maximum intended load during construction.

Safety features also deserve your attention. Look for guardrails that meet safety standards. These help prevent falls, which are a leading cause of accidents on construction sites. ANSI and OSHA regulations require certain height limits for guardrails. Compliance with these guidelines is not optional; it’s essential.

**Tips:** Always inspect your scaffolding before use. Ensure it has no visible defects. Also, consider modular designs. They can save time on assembly and are often more flexible in various environments. Choosing the right scaffolding can make a difference in productivity and safety. Investing in quality materials can prevent costly accidents. Reflect on your previous choices, and don’t rush the decision. It’s worth taking your time to get it right.

Factors Influencing the Cost of Steel Scaffolding

When purchasing steel scaffolding, various factors influence its cost. One significant aspect is the materials used in construction. High-grade steel tends to be more expensive, but it offers greater strength and durability. According to industry reports, scaffolding made from top-quality steel can improve safety on job sites. This is essential for reducing accidents and injuries.

Labor costs are another consideration. The installation of scaffolding requires skilled workers, influencing overall project budgeting. Additionally, rental vs. purchase decisions affect the total cost. Many companies prefer renting to lower initial expenses, but long-term projects may benefit from purchasing. Statistics show that rental costs can accumulate quickly—by as much as 20% over six months.

Lastly, geographical location impacts price variation. In areas with a higher demand for construction, steel scaffolding may command higher prices. Transportation costs also play a role. Local sourcing could help in reducing costs, but this might limit options. Reflecting on these elements can aid in making informed purchasing decisions.

Best Steel Scaffolding for Sale: What to Consider When Buying?

| Factor | Description | Estimated Cost Impact (%) |

|---|---|---|

| Material Quality | Higher quality steel increases durability and safety. | +20% |

| Height of Scaffolding | Taller scaffolds require more material and engineering. | +15% |

| Load Capacity | Scaffolding with higher load capacity usually costs more. | +10% |

| Design Complexity | Custom designs or intricate structures raise costs. | +25% |

| Regulatory Compliance | Meeting safety standards can add to manufacturing costs. | +5% |

| Accessory Components | Includes safety guardrails, ladders, and braces which boost functionality. | +8% |

| Shipping and Handling | Cost associated with transporting scaffolding to the job site. | +12% |

Safety Standards and Regulations for Steel Scaffolding

When purchasing steel scaffolding, it's crucial to understand the safety standards and regulations that apply. In the U.S., OSHA (Occupational Safety and Health Administration) outlines specific guidelines. These regulations ensure that scaffolding can support the intended loads and protect workers' safety. The average load capacity for scaffold systems is typically around 20 pounds per square foot. This measurement is vital, as exceeding it can lead to serious accidents.

Additionally, scaffolding must meet ANSI standards. According to a recent industry report, about 25% of scaffolding accidents occur due to improper assembly. Each component must be inspected before use. Regular inspections are essential for maintaining safety compliance. Specific training is necessary for anyone who will work on or around scaffolding. Ensuring workers are educated about potential hazards can reduce accidents significantly.

Moreover, personal protective equipment (PPE) should be mandatory. Workers should wear helmets, harnesses, and proper footwear. A focus on these details can make the difference between safety and tragedy. Despite regulations, non-compliance still occurs, indicating an ongoing need for vigilance. Scaffolding safety is not just about rules; it's about prioritizing human life above all else.

Safety Standards Compliance in Steel Scaffolding

Where to Find Reliable Steel Scaffolding Suppliers

When searching for reliable steel scaffolding suppliers, it’s essential to do thorough research. Look for companies with a solid track record in the industry. Check their experience and customer reviews. Verified suppliers often have a portfolio showcasing successful projects. Conversations with past clients can reveal important insights.

Local suppliers can be a smart choice. They understand regional construction needs. Proximity can reduce transportation costs. Don’t overlook online platforms. However, ensure they provide strong warranties and quality assurance. Visit their warehouses if possible. Inspect the materials and workmanship firsthand.

Be cautious of deals that seem too good to be true. Sometimes, lower prices mean compromised safety standards. Make safety a priority; it’s not worth the risk. Think about your specific project needs. Consider load-bearing capacities and sizes. It’s easy to assume all scaffolding is similar, but details matter greatly.

Article Source:

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org