2026 Best Welded Wire Mesh Options for Your Projects?

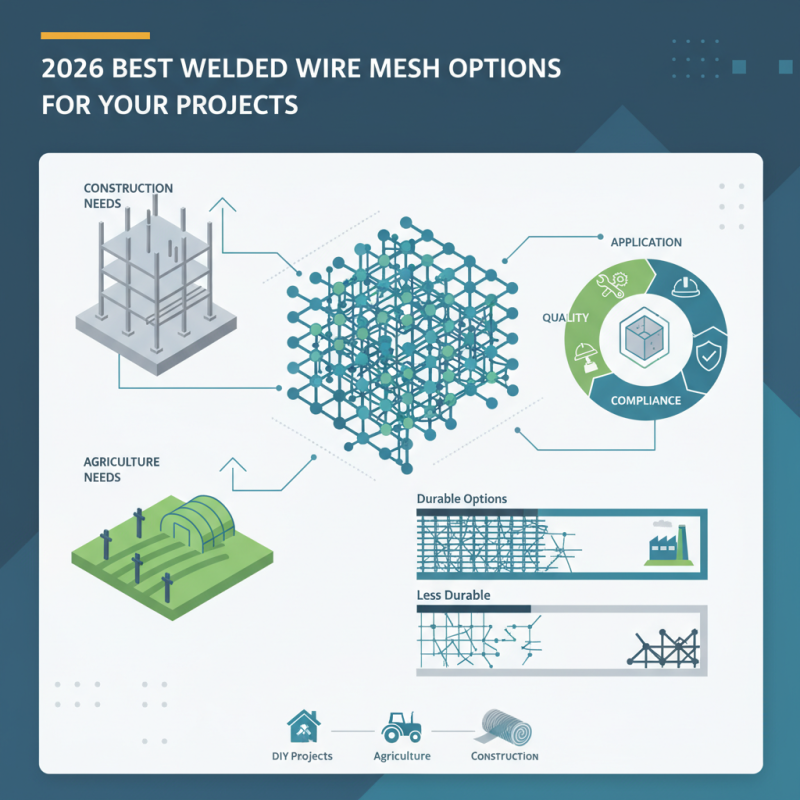

The demand for welded wire mesh has surged in recent years, as industries recognize its versatility and strength. According to a report by Research and Markets, the global welded wire mesh market is projected to grow significantly, driven by construction and agriculture needs. Expert John Smith, a renowned figure in the welded wire mesh industry, emphasizes, "Welded wire mesh is becoming essential for modern building practices due to its durability."

In various projects, welded wire mesh serves as a critical component. It provides support in concrete applications and enhances safety in fencing solutions. Yet, not all welded wire mesh options are created equal. Selecting the right type can be challenging, especially with the myriad of available choices. Some products may not meet durability standards, leading to potential failures in construction projects.

As stakeholders search for the best welded wire mesh options, it’s important to consider quality, application, and compliance. The right choice impacts structural integrity and overall project success. Reflecting on this growing trend offers valuable insights for anyone involved in construction, agriculture, or even DIY projects.

Best Welded Wire Mesh Types for Various Applications

When it comes to welded wire mesh, understanding the various types can greatly impact your projects. For fencing purposes, choosing a heavier gauge mesh is often ideal. It provides durability and security. These meshes resist wear and tear effectively. If you need something for garden applications, a lighter gauge may suffice. It allows plants to grow without obstruction.

Different projects might require different mesh sizes. Small openings work well for keeping pests out. Larger openings can be useful for more open structures, allowing airflow and light. Consider the environment where the mesh will be used too. Galvanized wire offers rust resistance, making it suitable for outdoor use. It’s essential to think about weather conditions in your area.

In construction, welded wire mesh plays a crucial role in concrete reinforcement. It ensures stability and increases strength. However, not all meshes are created equal. Sometimes, the choice between various versions can be challenging. Reflect on your specific needs to determine the best fit. Each type has its pros and cons that require careful consideration.

Factors to Consider When Choosing Welded Wire Mesh

Choosing the right welded wire mesh for your project requires careful consideration of several factors. Material type is crucial. Most welded wire meshes are made from low-carbon steel or stainless steel. Low-carbon steel offers strength and durability, while stainless steel provides excellent resistance to corrosion. According to industry reports, using stainless steel can increase lifespan by 40% in harsh environments.

Another important consideration is mesh size. Common sizes range from 1/2 inch to 6 inches. Smaller openings are suitable for gardening or small animal enclosures. Larger openings may work better for construction or fencing. A choice that doesn’t align with project needs can lead to unnecessary costs and inefficiencies.

Tip: Always check load-bearing requirements. Knowing how much weight the mesh will support helps prevent structural failures.

Finally, the finish of the wire mesh matters. Galvanized finishes resist rust and help maintain integrity over time. A poorly chosen finish can lead to premature wear or corrosion.

Tip: Inspect your mesh regularly. Over time, even the best materials can wear down. Keep an eye on any signs of damage or wear to ensure project longevity.

Top Manufacturers of Welded Wire Mesh in 2026

In 2026, the demand for welded wire mesh continues to rise across various industries. It is a staple in construction, agriculture, and manufacturing, providing robust support and stability. According to recent industry reports, the global welded wire mesh market is projected to grow at a CAGR of 5% between 2023 and 2028. This growth reflects the versatility and reliability of welded wire mesh.

Top manufacturers are focusing on innovation and quality control. They are investing in advanced technologies to enhance production efficiency. However, there are challenges to address. Some companies struggle with inconsistent quality, affecting overall satisfaction. Additionally, sourcing raw materials poses risks. Prices can fluctuate, leading to budget constraints.

Environmental concerns are also relevant. Sustainable practices are becoming essential in manufacturing processes. Consumers increasingly prefer eco-friendly options. The pressure to meet this demand is rising. Some manufacturers are not fully adapting, leaving a gap in the market. Addressing these issues will be crucial for sustained growth and competitiveness in 2026.

Comparative Analysis of Welded Wire Mesh Prices

When considering welded wire mesh options, pricing plays a crucial role. Recent industry reports indicate that the average cost for quality welded wire mesh ranges from $0.50 to $2.00 per square foot. This variance often depends on the gauge, mesh size, and material type. For example, a heavier gauge can be more expensive but provides superior durability.

Comparative analysis highlights that galvanized options tend to be pricier than PVC-coated ones. However, galvanized mesh often demonstrates longer life expectancy and better corrosion resistance. In contrast, PVC-coated mesh offers aesthetics but may wear out faster under certain conditions. This reflects the trade-offs between durability and budget constraints inherent in choosing the right mesh for a project.

Moreover, some suppliers feature significant price fluctuations throughout the year. This can affect project budgets and timelines. Understanding these dynamics is essential for making informed decisions. It's vital to reflect on what mesh quality best aligns with your long-term goals. Balancing between price and performance is a nuanced process. Ultimately, thoughtful analysis of prices and material attributes will lead to better project outcomes.

2026 Best Welded Wire Mesh Options for Your Projects

Installation Tips for Welded Wire Mesh Projects

When embarking on a welded wire mesh project, preparation is crucial. Proper installation can significantly affect durability and performance. According to a recent industry report, properly installed mesh can last up to 50 years, depending on conditions. Ensuring a clean foundation is vital. Soil should be compact and free of debris.

**Tip**: Use a level to check the ground before laying the mesh. A solid, even base prevents future warping or sagging. Reinforcement is often necessary. Consider overlapping seams by at least six inches. This ensures strength in your structure.

Weather impacts installation too. Avoid rainy days; moisture can affect adhesion. Dry surfaces enhance the longevity of any coating. Studies show that environmental factors can reduce a project's lifespan by 20% if not considered.

**Tip**: Always wear gloves while handling mesh. Sharp edges can cause injuries, making safety paramount. It's easy to overlook small details. Failing to secure the mesh adequately may lead to shifts and gaps. These small mistakes could compromise your entire project.

2026 Best Welded Wire Mesh Options for Your Projects - Installation Tips for Welded Wire Mesh Projects

| Mesh Type | Wire Diameter (mm) | Opening Size (mm) | Roll Size (m) | Weight (kg) | Ideal Application |

|---|---|---|---|---|---|

| Standard Welded Wire Mesh | 2.5 | 50 x 50 | 15 | 30 | Fencing, Garden Support |

| Heavy Duty Welded Mesh | 4.0 | 100 x 100 | 10 | 25 | Construction, Reinforcement |

| Wire Mesh for Ceilings | 1.5 | 25 x 25 | 20 | 18 | Interior Structures, Insulation |

| Gabion Welded Mesh | 3.0 | 70 x 100 | 2 | 50 | Retaining Walls, Erosion Control |

| PVC Coated Welded Mesh | 2.0 | 50 x 50 | 15 | 35 | Outdoor Fencing, Garden Decoration |

Article Source:

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org