How to Choose the Right Injection Machine Robot for Your Needs?

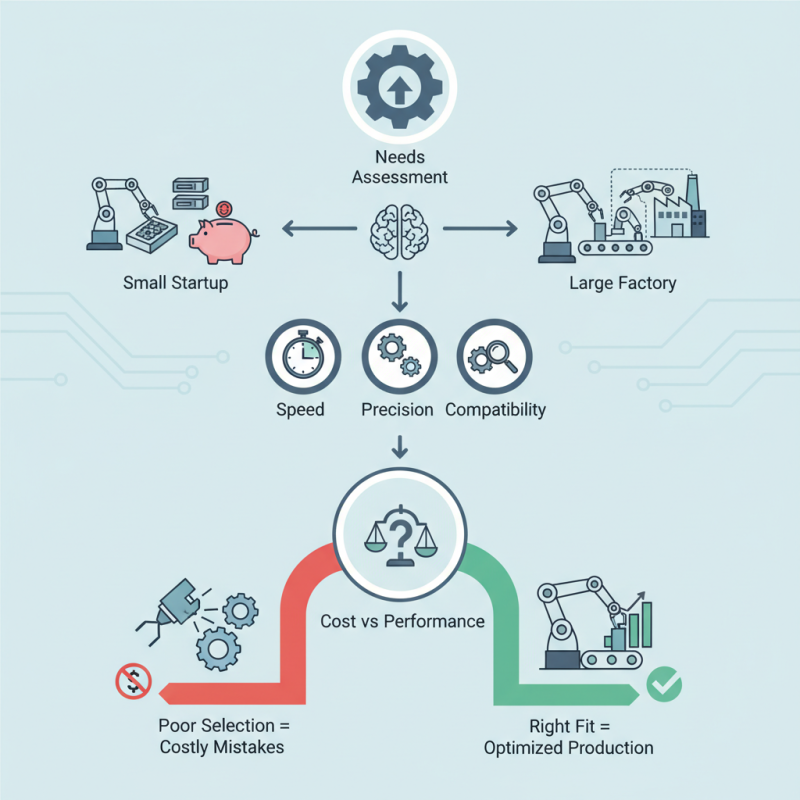

Choosing the right Injection Machine Robot is essential for optimizing production efficiency. In today's competitive manufacturing landscape, selecting the best fit can be challenging. Different factors come into play, affecting performance and output.

The complexities of injection molding mean that not all robots are created equal. Features like speed, precision, and compatibility with existing equipment matter greatly. You may think your needs are simple, but nuances can lead to costly mistakes. Whether a small startup or a large factory, each choice impacts productivity.

Understand that the ideal robot must align with your specific goals. You might find that one model looks appealing but lacks essential functions. Balancing cost against performance is key. Take time to evaluate various options, as the consequences of a poor selection can be significant.

Factors to Consider When Selecting an Injection Machine Robot

Choosing the right injection machine robot can be challenging. Several factors influence this decision. The type of material you'll be processing is crucial. Different materials may require specific robotic capabilities. Understanding your material’s viscosity and temperature requirements will guide you.

Another critical factor is the size of your operation. A small shop has different needs than a large factory. You need to consider the robot's reach and payload capacity. Additionally, the complexity of the parts you are producing matters. Simple shapes might require less sophisticated machines. However, intricate designs could demand advanced technology.

It's also important to think about the future. Industry demands may change, and your machine should adapt. Flexibility in programming is vital. You'll want a robot that can be easily reconfigured. Reflect on your long-term goals and how the machine will fit into them. You might face challenges in integrating new technology. This can lead to downtime if not planned well. Always weigh the pros and cons carefully before making a decision.

Types of Injection Machine Robots Available in the Market

When choosing an injection machine robot, understanding the types available is crucial. There are several main categories. These include articulated robots, SCARA robots, and delta robots. Each type has its unique strengths. Articulated robots are known for their flexibility. They can reach various angles and positions. This makes them ideal for complex tasks.

SCARA robots are simpler and faster. They work well for horizontal movements. This speed can enhance production efficiency. Delta robots, on the other hand, are great for picking and placing items quickly. They excel in high-speed environments. However, they may lack the versatility of articulated robots.

Tips: Consider the space in your facility. Some robots require more room to operate than others. Think about your production needs too. Will you be handling heavy items or delicate components? Remember, sometimes a less sophisticated robot will do the job just fine. Reflecting on your actual needs can help avoid over-investment.

Assessing Your Production Needs and Output Requirements

Choosing the right injection machine robot requires a clear understanding of your production needs. Assess the size and complexity of your parts. Consider how often you need to switch between different products. This variability can dictate the flexibility of the robot you need. A high mix of products may require a more adaptable machine. A high volume of a single item could benefit from a specialized setup.

Your output requirements are crucial. Determine your desired production speed and cycle times. If you're aiming for high output, the robot's efficiency becomes essential. Evaluate how many cycles per hour you need. Keeping these metrics in mind helps to align the robot's capabilities with your processes. Monitoring production statistics can reveal areas for improvement.

Communication with your team is vital. Employees can offer insights into bottlenecks and production challenges. Sometimes, operator feedback can highlight the need for changes. Remember, the machine that fits today’s production may not suit future needs. Regular assessment is necessary, as requirements evolve over time.

Injection Machine Robot Production Needs Assessment

Evaluating Budget and Cost-Effectiveness of Different Models

When evaluating budget and cost-effectiveness for injection machine robots, it’s crucial to assess the total cost of ownership (TCO). A recent study found that operational costs can account for up to 70% of TCO over a machine's lifespan. This includes maintenance, energy consumption, and replacement parts. Opting for a more expensive model may seem counterintuitive, but it can lead to lowered operational costs through efficiency gains.

Consider the efficiency rating of various models. For example, machines that utilize servo drives can improve energy efficiency by 50% compared to traditional hydraulic systems. This can significantly reduce electricity bills in high-production environments. However, these advanced models come with a higher initial price tag, which may strain tight budgets. It's vital to calculate potential savings to make an informed decision.

Another vital factor is performance reliability. According to industry reports, robots that experience frequent downtime can cost manufacturers thousands annually. Investing in a machine with a strong track record may incur higher upfront costs but could save money in the long run. Nevertheless, balancing initial costs with long-term returns requires careful consideration. Pricing should not be the only focus; performance, energy efficiency, and maintenance must also influence the choice.

Understanding Technical Specifications and Features of Robots

When selecting an injection machine robot, understanding technical specifications is crucial. Key features include payload capacity, speed, and precision. These aspects directly impact the robot's performance in various applications. For example, a robot with a higher payload can handle heavier molds, which may be essential for specific production needs. Meanwhile, speed influences cycle times. A faster robot can significantly boost productivity.

Another important specification is the robot's reach. It determines how far the robot can operate. A robot with a limited reach may not fit well in larger setups. It can lead to inefficiencies or the need for additional equipment. Likewise, the motion control system plays a vital role in accuracy. Inconsistent movements can result in defects.

Look at the ease of programming. Complex interfaces may slow down setup times. Some robots require skilled operators, which adds to costs. On the other hand, intuitive programming can enhance user experience. Don't overlook safety features, either. They are essential in preventing accidents during operation. Ultimately, assess how these specifications align with your production goals.

How to Choose the Right Injection Machine Robot for Your Needs?

| Specification | Value |

|---|---|

| Payload Capacity | 5 kg - 200 kg |

| Reach | 500 mm - 3000 mm |

| Speed | 0.1 m/s - 2 m/s |

| Precision | ±0.01 mm - ±0.5 mm |

| Control Type | Servo Control / Pneumatic |

| Communication Interface | Ethernet / USB / RS232 |

| Operating Environment | Indoor / Dust-Free |

| Programming Languages | RoboGuide / Python |

Article Source:

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org