Understanding Electric Hoist Specifications for Global Buyers

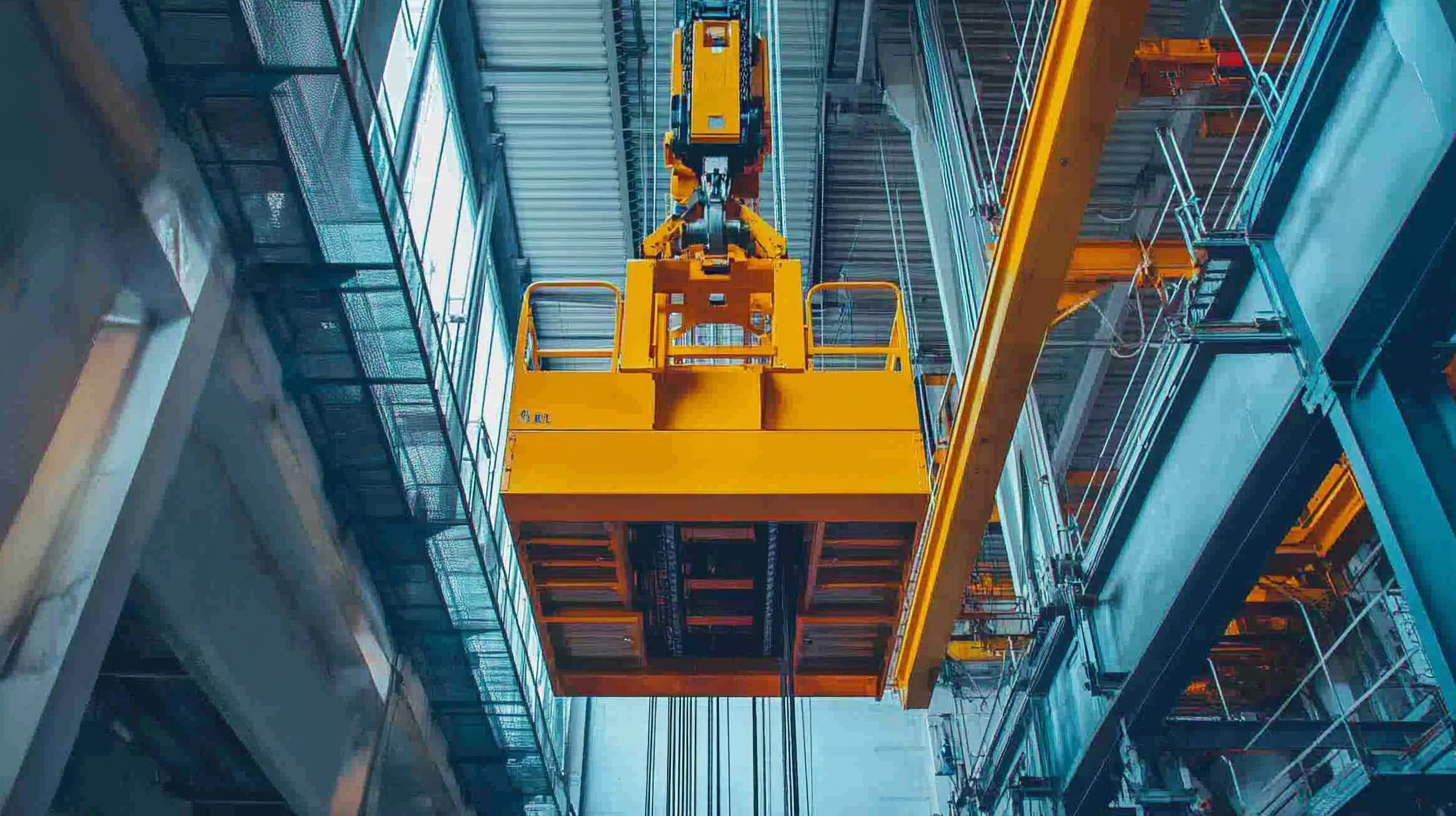

In recent years, the electric hoist market has experienced significant growth, driven by the increasing demand for efficient lifting solutions across various industries. According to a report by Research and Markets, the global electric hoist market is projected to reach USD 3.9 billion by 2025, growing at a CAGR of 5.1% from 2020 to 2025. This growth is largely fueled by the expansion of construction activities, advancements in technology, and the rising adoption of automation. As businesses and industries worldwide recognize the advantages of electric hoists, understanding their specifications becomes crucial for global buyers seeking to optimize their operations.

Electric hoists play a pivotal role in enhancing productivity and ensuring safety; therefore, buyers must navigate through a myriad of specifications that can directly impact their effectiveness. Key factors including lifting capacity, speed, power source, and control mechanisms are essential considerations for making informed purchasing decisions. Industry studies highlight that buyers often overlook these parameters, leading to inadequate equipment choices that could hinder operational efficiency. This blog aims to demystify electric hoist specifications, offering valuable insights for global buyers to make informed selections that align with their specific needs and enhance their operational success.

Key Metrics to Consider When Evaluating Electric Hoist Specifications

When purchasing electric hoists, global buyers must carefully evaluate several key metrics that can significantly impact performance and safety. One of the primary considerations is the lifting capacity, which determines the maximum weight the hoist can safely lift. It is crucial to select a hoist that matches not only the anticipated load but also provides a margin for safety to prevent overload situations. The capacity specifications often vary widely across different models, so buyers should ensure that the chosen hoist can accommodate their specific operational needs. Another essential metric is the lift speed, which affects the efficiency and productivity of lifting operations. Buyers should look for hoists that offer optimal speeds for their applications, considering the type of materials being lifted and the work environment. A balance between speed and control is vital to enhance workflow while ensuring precision during operations. Additionally, the duty cycle rating indicates how often the hoist can be used in a given time frame without overheating. Understanding these cycles helps buyers select equipment that can maintain performance levels without risking equipment failure. Finally, the power source of the electric hoist—whether it operates on single-phase or three-phase electricity—should be matched to the electrical infrastructure available at the operation site. This consideration is important not only for compatibility but also for maximizing energy efficiency. Moreover, features such as remote control options, safety mechanisms, and warranty coverage should also be carefully assessed. These specifications play a critical role in ensuring that the chosen hoist meets both the safety and operational requirements, ultimately contributing to a more productive working environment.

Understanding Load Capacity and Safety Margins in Electric Hoists

When considering the purchase of electric hoists, understanding load capacity and safety margins is crucial for ensuring effective and secure material handling. Load capacity refers to the maximum weight an electric hoist can lift safely, a vital specification that varies widely among models and manufacturers. According to an industry report by Research and Markets, the global electric hoist market is expected to grow at a CAGR of 4.1% from 2021 to 2026, underscoring the increasing relevance of these specifications for global buyers.

A common guideline in the industry is to maintain a safety margin of at least 20% above the hoist's rated capacity. This means that if an electric hoist has a load capacity of 1000 kg, it should ideally handle no more than 800 kg during regular operation to accommodate unexpected stresses and ensure long-term reliability. The American Society of Mechanical Engineers (ASME) advises that safety margins are non-negotiable, especially in industries like construction and shipping, where the stakes are significantly high.

Moreover, understanding the different types of load conditions—static, dynamic, and shock loads—is essential for assessing the appropriate safety margins. A study by the International Organization for Standardization (ISO) highlights that shock loading can significantly exceed the rated capacity momentarily, which could lead to equipment failure if not accounted for. Therefore, buyers must not only consider the stated load capacity but also evaluate the specific application and operational conditions to choose an electric hoist that meets safety requirements.

Types of Electric Hoists: Choosing the Right Fit for Your Project

Electric hoists are vital components in the construction and manufacturing sectors, especially as industries look to enhance efficiency and safety. As global buyers consider different types of electric hoists, understanding the specific needs of their projects becomes paramount. According to recent industry reports, the global electric hoist market is expected to grow significantly, driven by the increasing demand for automation in various sectors. Currently, electric hoists maintain a penetration rate of just 1% within the larger engineering machinery sector, suggesting that there are extensive opportunities for growth.

When selecting the right electric hoist, potential buyers should consider the various types available, including rope hoists, chain hoists, and wire rope hoists. Each type serves different applications depending on the lifting capacity, height requirements, and operational environment. For instance, chain hoists are preferred for heavier loads and more rigorous environments, while wire rope hoists excel in applications requiring higher speeds and longer lifting heights. The right choice not only improves efficiency but also enhances workplace safety by minimizing potential risks associated with manual lifting operations.

The shift towards electricization in engineering machinery is gaining momentum, necessitating a deeper understanding of electric hoist specifications. Reports indicate that as companies look to modernize their fleets, the emphasis will be on selecting equipment that meets stringent safety standards while delivering optimal performance in various industrial applications. As the industry moves toward greater automation, buyers must remain agile and informed to select electric hoists that not only fit their immediate project needs but also align with future developments in electric machinery.

Motor Power and Performance: How They Affect Hoisting Efficiency

When selecting an electric hoist, understanding motor power and performance is crucial for maximizing hoisting efficiency. The motor is the heart of the hoist, dictating not just how much weight it can lift, but also the speed and reliability of the operation. A higher motor power typically correlates with an increased lifting capacity, allowing the hoist to handle heavier loads without compromising performance. Therefore, global buyers must pay close attention to the specifications when choosing the right hoist for their needs.

Performance metrics such as duty cycle and lifting speed are also essential considerations. The duty cycle, which indicates how long a hoist can operate at full load before needing a break, directly impacts overall productivity. For instance, a hoist suited for continuous operation will often feature a more robust motor, designed to withstand prolonged use. Similarly, the lifting speed can significantly affect efficiency, especially in time-sensitive operations. A faster hoist reduces wait times, enabling smoother workflow and higher throughput within industrial settings.

Understanding these specifications enables buyers to evaluate how different electric hoist models might align with their operational demands. By prioritizing the right motor power and performance features, they can ensure that their investment not only meets their immediate lifting needs but also promotes long-term sustainability and efficiency in their operations.

Global Compliance Standards: Ensuring Your Hoist Meets International Requirements

When it comes to electric hoists, understanding global compliance standards is crucial for buyers aiming to navigate the international market. Adhering to these standards not only ensures safety and efficiency but also helps manufacturers streamline their operations across borders. For instance, certifications such as ISO and CE mark the hoists that meet rigorous performance criteria, which is especially significant for companies looking to expand their reach while maintaining high safety standards.

In a world where technological innovations are on the rise, staying compliant with these specifications becomes even more vital. Recent advancements in various industries, such as the pioneering integrated offshore hydrogen and ammonia project in China, underline the importance of adhering to global standards. This project represents a significant leap towards sustainable energy solutions, and similar innovations in material handling equipment must also prioritize compliance to foster growth and trust in the global market.

As electric hoists become increasingly integral to the logistics and construction sectors, ensuring they meet international requirements can facilitate smoother transactions and broader market access. Buyers should remain vigilant about verifying compliance documents and certifications to ensure they are investing in equipment that not only meets local demands but can also compete on a global scale.

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org