The Future of Pneumatic Chain Hoists: Innovations Shaping Industrial Lifting Solutions

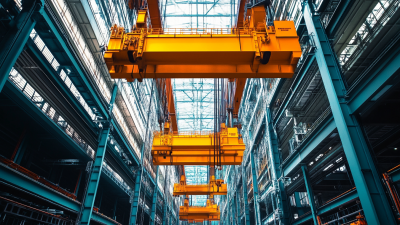

In recent years, the industrial lifting sector has witnessed significant advancements, particularly in the realm of Pneumatic Chain Hoists. As businesses seek more efficient and reliable solutions for their lifting needs, these hoists have emerged as a compelling choice, combining innovative technology with robust performance. This blog delves into the future of Pneumatic Chain Hoists, exploring the latest innovations that are not only enhancing their functionality but also improving safety and energy efficiency in various industrial applications. By comparing traditional lifting systems with the cutting-edge developments in Pneumatic Chain Hoists, we aim to highlight the transformative potential of these tools in revolutionizing operational workflows, reducing downtime, and ultimately driving productivity. Join us as we examine the critical trends and technologies that are shaping the next generation of industrial lifting solutions.

Key Innovations in Pneumatic Chain Hoist Technology

The pneumatic chain hoist industry is witnessing transformative innovations that promise to enhance efficiency and sustainability in industrial lifting solutions. One pivotal development is the emergence of emission-free pneumatic controllers, which aim to replace costly natural gas-powered systems. As the industry grapples with the pressing need for eco-friendly practices, these advancements align with broader environmental goals, enabling operators to reduce their carbon footprint while maintaining high performance in operations.

According to industry reports, the global pneumatics market is projected to rebound in 2025, spurred by ongoing technological advancements. This positive outlook is bolstered by innovations such as adjustable wheel technology, which optimizes hoist operations over various terrains by adapting stiffness dynamically. Such enhancements not only increase the versatility of pneumatic systems but also drive productivity improvements across diverse applications. With these innovations, pneumatic chain hoists are set to play a crucial role in the evolution of industrial lifting solutions, marrying efficiency with sustainability.

The Future of Pneumatic Chain Hoists: Innovations Shaping Industrial Lifting Solutions

| Innovation | Description | Benefit | Impact on Industry |

|---|---|---|---|

| Smart Controls | Integration of IoT for remote monitoring and control. | Increased efficiency and reduced downtime. | Enhances operational capabilities and workforce safety. |

| Lightweight Materials | Usage of advanced composites for hoist construction. | Easier handling and increased portability. | Facilitates lifting in constrained spaces and reduces labor costs. |

| Energy Efficiency | Improvements in pneumatic systems for less energy consumption. | Lower operational costs and environmental impact. | Supports sustainability goals for industries. |

| Enhanced Safety Features | Implementing automatic shut-off and fall protection systems. | Improved worker safety and reduced accident risks. | Cultivates a safety-first culture in the workplace. |

| Modular Design | Flexible and customizable hoist configurations. | Adaptable to varying lifting needs. | Increases versatility in industrial applications. |

Advantages of Pneumatic Chain Hoists Over Traditional Lifting Solutions

Pneumatic chain hoists are rapidly becoming the preferred choice in various industrial applications, thanks to their distinct advantages over traditional lifting solutions. One key benefit is their ability to operate efficiently in hazardous environments where electric hoists may present safety risks. Pneumatic-powered systems utilize compressed air, eliminating the risk of electrical sparks and making them ideal for industries such as oil and gas, chemical manufacturing, and food production.

Recent market analyses indicate that the global market for pneumatic hoists is projected to grow significantly, driven by advancements in technology and increasing demands for safety and productivity. For instance, pneumatic hoists can lift heavy loads at a consistent speed without overheating, which is a common issue faced by electric hoists. Additionally, with innovations in design, modern pneumatic hoists have become more compact and easier to handle, enhancing operational efficiency. These advancements also allow for seamless integration into automated systems, further boosting productivity rates in dynamic lifting environments.

Moreover, the introduction of high-performance pneumatic hoisting equipment in emerging markets, such as Southern Africa, signifies a shift towards more reliable and robust lifting solutions. As industries continue to prioritize safety and operational efficiency, pneumatic chain hoists will likely dominate the market, offering a compelling alternative to traditional lifting methods.

Impact of Automation on the Future of Pneumatic Lifting Systems

The integration of automation technologies into pneumatic lifting systems is set to revolutionize industrial lifting solutions, enhancing efficiency and safety. According to a report from MarketsandMarkets, the global market for industrial automation is anticipated to grow from $175 billion in 2020 to over $300 billion by 2025, indicating a strong push towards automated solutions across industries. Pneumatic chain hoists, traditionally manual in operation, are increasingly being equipped with sensors and controls that allow for remote operation and precise load management. This shift not only minimizes human error but also optimizes operational workflows.

Moreover, advancements in IoT (Internet of Things) are fostering smarter pneumatic lifting systems that offer real-time data analytics. For instance, a study by Research and Markets highlights that IoT-enabled machinery can increase operational efficiency by up to 30%. By employing predictive maintenance protocols powered by automated data collection, companies can reduce downtime and extend the lifespan of their equipment. As industries strive for greater productivity, the marriage of pneumatic lifting systems and automation technologies is undeniably shaping the future of material handling in complex industrial environments.

Sustainability Trends in Pneumatic Chain Hoist Design

As industries worldwide continue to prioritize sustainability, the design of pneumatic chain hoists is evolving to meet these growing demands. Recent studies indicate that around 70% of industrial decision-makers are now placing a higher emphasis on environmentally friendly equipment. Innovations in pneumatic chain hoists are focusing on energy efficiency and the use of sustainable materials. Manufacturers are incorporating lightweight composites and recyclable metals, reducing the overall environmental footprint during production and throughout the product lifecycle.

**Tip:** When selecting a pneumatic chain hoist, look for models that feature energy-efficient motors and systems designed to minimize air consumption. This not only contributes to lower operational costs but also enhances your company's sustainability profile.

Furthermore, advancements in technology are enabling real-time monitoring and analytics, which facilitate more efficient operation and maintenance. According to a report by Industrial Equipment Insights, companies that invest in intelligent lifting solutions see a reduction in energy usage by up to 30%. By optimizing usage patterns and ensuring timely maintenance, businesses can significantly lower their emissions and resource consumption.

**Tip:** Regularly schedule maintenance checks and utilize monitoring tools to track your hoist’s performance. Staying proactive can help you identify inefficiencies early, promoting both sustainability and profitability.

The Future of Pneumatic Chain Hoists: Innovations Shaping Industrial Lifting Solutions

Industry Applications Driving Demand for Advanced Pneumatic Hoists

The growing demand for advanced pneumatic chain hoists can largely be attributed to their significant applications across various industries. In manufacturing and construction, these lifting solutions offer enhanced efficiency and safety, enabling workers to transport heavy materials with precision and ease. The ability to operate in hazardous environments without the risk of electrical hazards makes pneumatic hoists especially appealing for industries like oil and gas, where flammable materials are prevalent.

Innovations in design and technology are further driving the adoption of pneumatic hoists. Modern advancements include features like variable speed controls and improved energy efficiency, which cater to the evolving needs of fast-paced industrial operations. Moreover, the integration of smart technology allows for real-time monitoring and diagnostics, ensuring optimal performance and reducing downtime.

With the relentless push for automation and higher productivity in industrial settings, pneumatic hoists are increasingly becoming indispensable tools in the lifting arsenal.

Related Posts

-

Ultimate Guide to Choosing the Right Chain Hoist for Your Business Needs

-

Challenges Facing Buyers When Choosing the Best Manual Chain Hoist

-

Maximize Your Exports with Manual Hoists at the Record Breaking Canton Fair 2025

-

Embracing Industry 2025 Innovations Discover the Best Download Full Catalog for Global Buyers

-

Elevating Global Standards: The Rise of Premium Chain Come Along from China

-

7 Essential Features of the Best Manual Hoist for Your Business

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org