What is a Lever Hoist and How Does it Work?

A Lever Hoist is an essential tool in material handling, widely used across various industries. John Smith, a lifting equipment expert, once stated, "The right tool can make all the difference in safety and efficiency." This simple yet powerful device can lift heavy loads with minimal effort. Unlike other hoisting tools, the Lever Hoist combines mechanical advantage with ease of use.

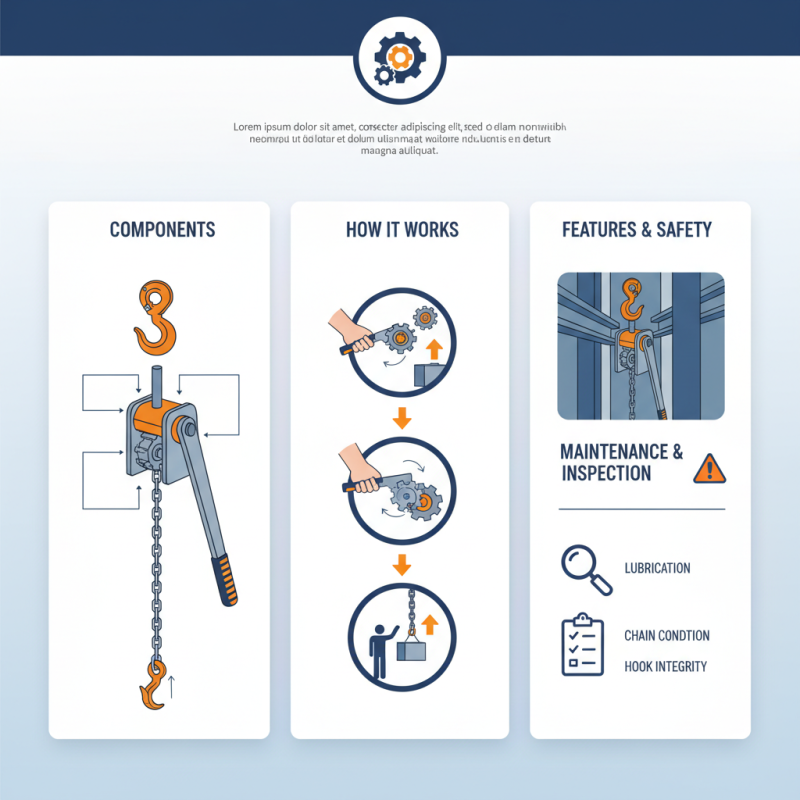

Understanding how a Lever Hoist works is crucial for anyone involved in lifting and rigging tasks. Operators should know its components, such as the hook, lever arm, and ratchet. With proper training, users can harness its full potential. However, improper use can lead to accidents or failures.

The Lever Hoist is compact and portable, making it ideal for tight spaces. Yet, it requires regular maintenance to remain effective. A small oversight can result in significant problems. Simple checks can prevent dangerous situations. This tool embodies the need for focus and attention to detail in heavy lifting.

What is a Lever Hoist?

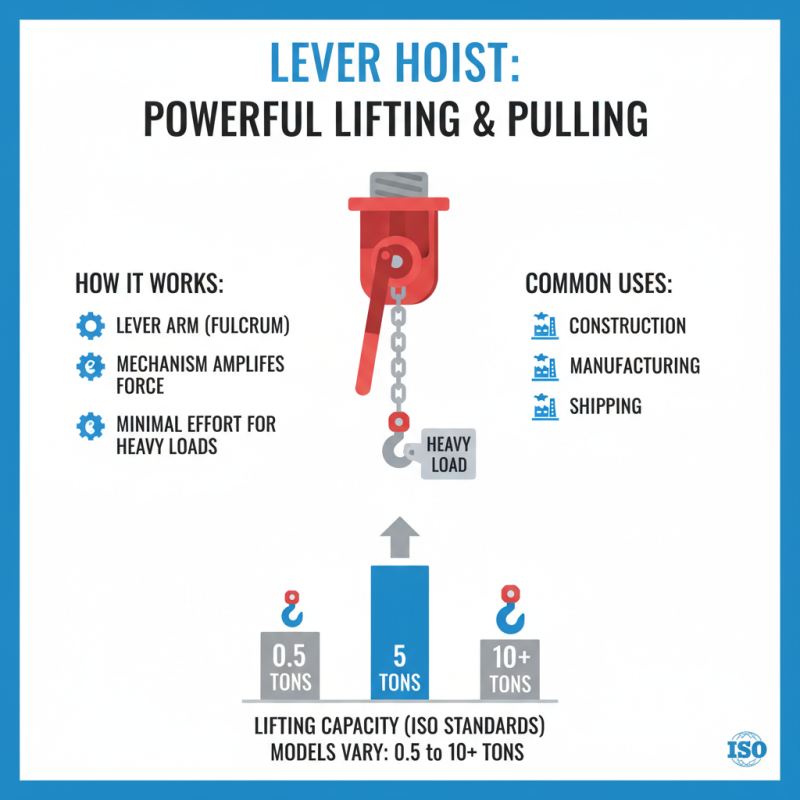

A lever hoist is a simple, yet powerful tool used primarily for lifting and pulling heavy loads. Its design consists of a lever arm, which acts as a fulcrum. The mechanism allows users to lift objects efficiently with minimal effort. Industries such as construction, manufacturing, and shipping commonly use lever hoists. According to the International Organization for Standardization (ISO), these tools can lift loads ranging from 0.5 tons to over 10 tons, depending on the model.

The operation of a lever hoist involves a ratchet-and-pawl system. This system ensures that the load remains suspended while adjustments are made. Users pull down on the lever. This action creates mechanical advantage, allowing them to lift heavy items while exerting less force. A report from the Occupational Safety and Health Administration (OSHA) emphasizes proper training to prevent accidents. Users must know load limits and operating procedures to avoid mishaps.

Despite their advantages, lever hoists require careful handling. Improper use can lead to injuries or accidents. Regular maintenance is necessary to ensure that they function correctly. Any signs of wear or damage should be addressed immediately. A survey by the American Society of Safety Professionals shows that effective training can reduce workplace accidents by up to 30%. Understanding the lever hoist's mechanics is vital for safety and efficiency.

Key Components of a Lever Hoist

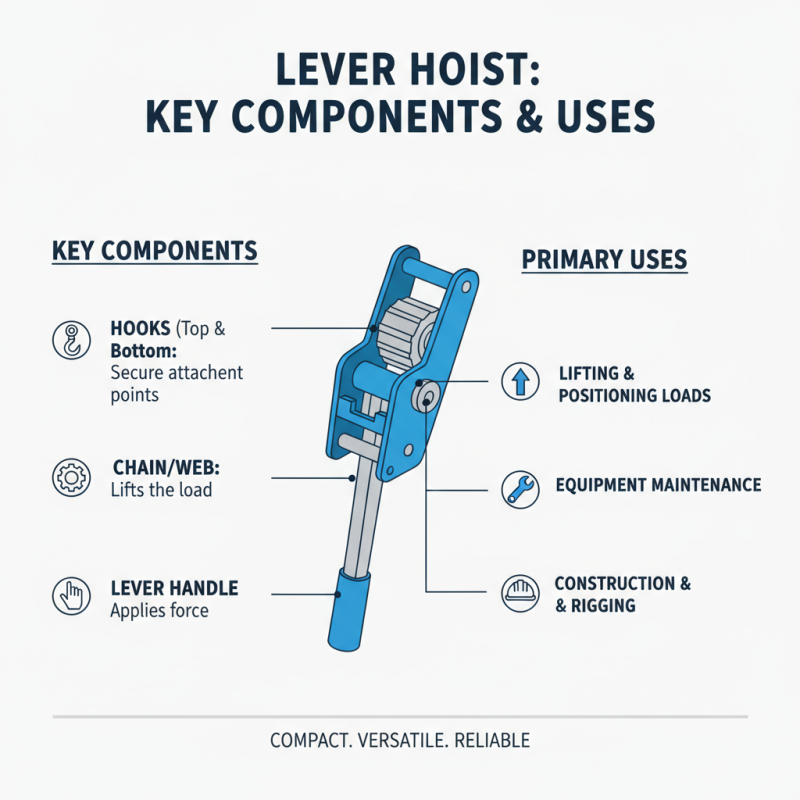

A lever hoist is a manual device used for lifting and lowering heavy loads. It’s compact and versatile, making it ideal for various applications. Understanding its key components helps in operating it effectively.

The main part of a lever hoist is the lever arm. This arm allows the user to apply force, making lifting easier. The load chain is another crucial component; it’s the part that actually lifts the load. The chain wraps around a sprocket, connecting to the hook that holds the load. Inspecting the chain for wear or damage is essential for safety.

The ratchet lever is also significant. It engages with the load chain, preventing it from slipping back down. A pawl is present to lock the ratchet in place when lifting. These parts work together to create a reliable lifting device. However, users need to be mindful. Incorrect use can lead to accidents. Regular maintenance is necessary to ensure everything functions correctly. Understanding these components fosters not only safety but also efficiency in lifting tasks.

How Lever Hoists Operate Mechanically

A lever hoist is a mechanical tool widely used to lift heavy loads with minimal effort. Operating a lever hoist involves a simple yet effective mechanism. The design includes a lever, hook, and a ratchet system. When the lever is pulled down, it creates mechanical advantage. This action multiplies the force exerted by the operator, allowing them to lift substantial weights, sometimes exceeding 5 tons.

Research from industry reports indicates that lever hoists can achieve lift ratios up to 10:1. This means that a mere 10 pounds of effort can raise 100 pounds of weight. However, incorrect usage or overload can lead to mechanical failure. It's important to regularly inspect the device, as wear and tear can compromise safety. Even seasoned operators may overlook signs of wear, resulting in unsafe lifting.

The key to effective operation lies in understanding the mechanical principles at play. Lever hoists utilize gravitational forces and leverage. However, knowing the limitations is crucial. Miscalculating load weight can result in accidents or damage to the hoist. Operators should focus on proper training and maintenance to ensure safe use.

What is a Lever Hoist and How Does it Work? - How Lever Hoists Operate Mechanically

| Feature | Description | Usage | Load Capacity (tons) |

|---|---|---|---|

| Mechanical Advantage | Utilizes a lever mechanism to lift heavy loads efficiently. | Ideal for construction and industrial applications. | 0.5 to 10 |

| Construction Material | Typically made from high-strength steel for durability and safety. | Suitable for outdoor and rugged environments. | Varies based on model. |

| Operation | Operated manually by pulling the lever handle. | Used for lifting, lowering, or pulling objects. | Up to 10 |

| Safety Features | Includes a safety latch and overload protection systems. | Maintains safety during heavy lifting operations. | Standard across models. |

| Portability | Lightweight and compact design for easy transport. | Perfect for on-site applications and emergency situations. | Compact models available. |

Common Applications of Lever Hoists

Lever hoists are versatile tools commonly used in various industries. These mechanical devices, designed to lift and move heavy loads, prove invaluable in construction, shipping, and manufacturing. According to industry reports, the global lever hoist market is projected to grow at a CAGR of about 5.1% over the next five years. This growth underlines their importance in handling materials safely and efficiently.

In construction sites, lever hoists assist in lifting materials, tools, and equipment. They can lift loads exceeding 3 tons. This capability makes them essential for erecting structures or moving heavy machinery. In shipping yards, workers often deploy lever hoists for securing cargo. The ability to adjust the load easily enhances operational efficiency. Manufacturers also utilize lever hoists during assembly processes, moving parts that weigh hundreds of pounds. They contribute to smoother workflows and minimize downtime. However, with heavy use, maintenance becomes crucial. Neglecting this aspect can lead to accidents or equipment failure.

Despite their advantages, using lever hoists requires training. Incorrect operation can lead to dangerous situations. Regular safety audits can help address this issue. Establishing protocols and ensuring staff are well-trained is vital. Striking a balance between efficiency and safety will create a better work environment. Lever hoists play a significant role, but their operation must be constantly reviewed and refined for optimal results.

Safety Considerations When Using Lever Hoists

When using lever hoists, safety should always come first. Proper training is essential. Operators need to understand how to handle the device effectively. Wearing the right protective gear is also crucial. This includes gloves and safety glasses. Remember, a minor oversight can lead to serious accidents.

Before using a lever hoist, inspect it thoroughly. Check for any wear or damage. The chains should be intact, and the hooks should pivot smoothly. If something feels off, don't use the hoist. A failed mechanism can lead to dropped loads. This could result in injuries to nearby workers.

In addition, be aware of the load limits. Overloading a lever hoist poses significant risks. It can cause mechanical failure or injury. Always use the hoist on a flat, stable surface. Avoid uneven grounds. The setup should also include proper anchor points. When in doubt, consult safety guidelines. Reflect on past experiences as well. Mistakes can teach valuable lessons. Stay alert and ensure a safe working environment.

Related Posts

-

How to Maximize Safety and Efficiency with Lever Hoist in Industrial Applications

-

The Definitive Ultimate Guide to Choosing the Best Chain Fall Hoist for Your Needs

-

7 Essential Features of the Best Manual Hoist for Your Business

-

The Ultimate Guide to Choosing the Right Chain Come Along for Your Needs

-

12 Top Advantages of Using Crane Hoists in Modern Industries

-

Innovative Uses of Electric Chain Fall in Modern Industries

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org