Top 10 Manual Hoist Safety Tips You Need to Know?

Manual hoists are essential tools in various industries, from construction to warehousing. According to the U.S. Bureau of Labor Statistics, around 30% of workplace injuries involve lifting and moving heavy loads. This emphasizes the importance of implementing safety measures when using manual hoists. While these devices are vital for efficient operations, they can pose risk factors if not handled correctly.

Inadequate training and poor maintenance can lead to accidents. Statistics from the Occupational Safety and Health Administration indicate that improper use of lifting equipment contributes to a significant percentage of workplace injuries. Companies must prioritize safety to ensure their workers are protected. Understanding the potential hazards associated with manual hoist use can make a difference.

As workplaces evolve, the need for safety awareness is more critical than ever. Despite regulations, accidents may still happen. Evaluating safety practices around manual hoists is necessary for protecting personnel and improving operational efficiency. These reflections can help foster a culture of safety that minimizes risks and enhances productivity.

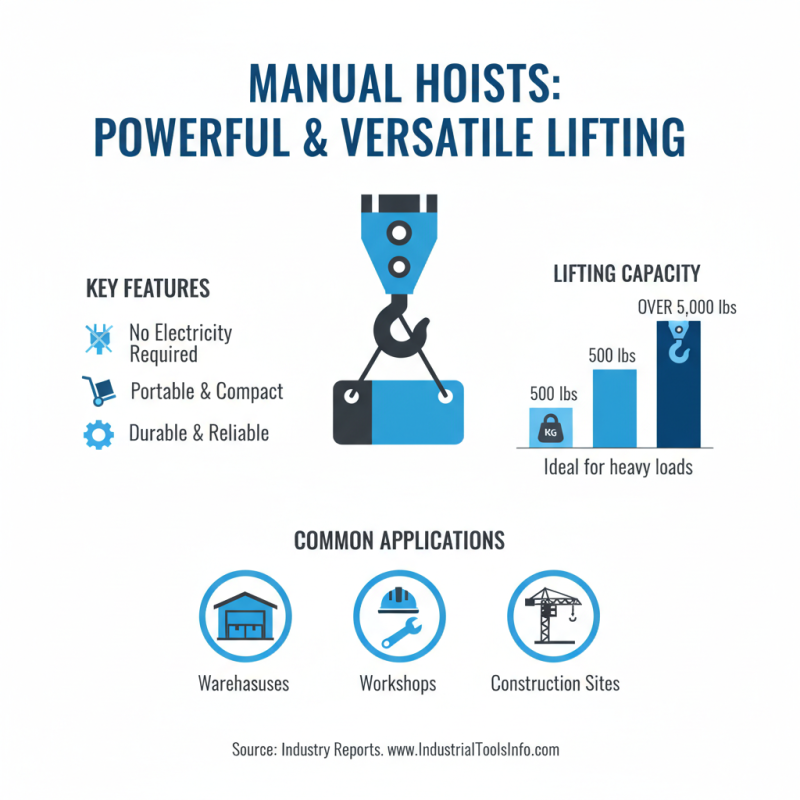

Understanding the Basics of Manual Hoists and Their Uses

Manual hoists are essential tools in various industrial settings. They facilitate lifting heavy loads without relying on electricity or complex machinery. According to industry reports, manual hoists can support weights ranging from 500 to over 5,000 pounds. This versatility makes them popular in warehouses, construction sites, and mechanical workshops.

Using manual hoists requires an understanding of their limitations. For example, incorrect lifting techniques can lead to accidents. Studies indicate that improper hoisting accounts for 25% of workplace injuries related to lifting. Users must be trained to operate these devices safely. Regular inspections are vital, as wear and tear can lead to malfunctions.

Safety is paramount when using manual hoists. Workers should always wear suitable protective gear. It's crucial to assess the load and the lift's environment before usage. The lack of proper planning can lead to dangerous situations. Recognizing these risks is essential for maintaining a safe workplace.

Identifying Common Hazards Associated with Manual Hoists

Manual hoists are vital in many industrial settings, but they come with risks. Common hazards include improper use and inadequate training. Workers may underestimate the weight limits, leading to accidents. Always ensure employees are trained on correct lifting techniques. It’s crucial they understand how to calculate load weight accurately.

Another significant hazard is equipment wear and tear. Ropes and chains can fray or stretch over time, making them less reliable. Regular inspections are essential. Workers should check the hoist before each use for signs of damage. A worn-out hoist is a ticking time bomb.

Environmental factors also play a role in safety. Slippery floors or poor lighting can create dangerous conditions. Ensure work areas are clean and well-lit. It’s easy to overlook these details, but they are vital for safety. Even small spills can lead to big accidents. Encourage a culture of safety awareness to minimize risks effectively.

Top 10 Manual Hoist Safety Tips You Need to Know

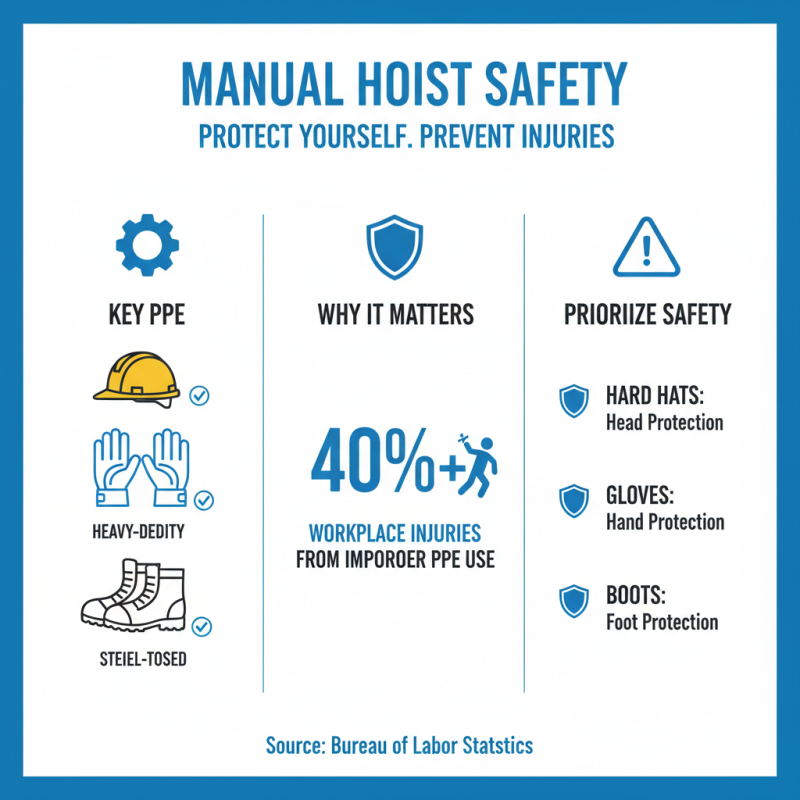

Essential Personal Protective Equipment (PPE) for Hoisting Safety

When working with manual hoists, personal protective equipment (PPE) is crucial for ensuring safety. Key pieces of PPE include hard hats, gloves, and steel-toed boots. According to the Bureau of Labor Statistics, over 40% of workplace injuries occur due to improper PPE use. This statistic highlights the need for workers to prioritize their safety gear.

Hard hats protect against head injuries from falling objects. They should fit properly and be inspected regularly. Gloves help prevent hand injuries from sharp edges or heavy loads. The right type of glove can significantly reduce the risk of cuts and abrasions. Steel-toed boots provide vital protection for the feet and support stability, reducing slips and falls.

Proper training on using PPE is often overlooked. Workers may feel invulnerable without it. An alarming 68% of workers reported that they do not receive thorough training about their safety equipment. This gap can lead to accidents. It is essential for employers to emphasize ongoing training sessions. Continuous education on PPE can bridge this dangerous understanding gap.

Proper Inspection Procedures for Manual Hoists Prior to Use

When using manual hoists, proper inspection is crucial. Before each use, check the hoist's body for any signs of wear or damage. Look for rust, cracks, or unusual dents. Pay special attention to the hooks. They should rotate freely and not have any deformation. A little scratch may seem minor, but it can indicate deeper issues.

The chain is another focus area. Check for corrosion or twisting. Test the lifting mechanism to ensure it operates smoothly. Any unusual noises during operation should trigger immediate attention. Don't overlook the manual's instructions; they can provide key insights. One often forgotten aspect is the safety latch on the hook. Ensure it closes securely to prevent accidents.

Remember, your environment matters. Clear any debris around the hoist area. Ensure that the surface is stable. While inspections are important, they can easily be rushed. Taking time to observe your equipment can save lives. Neglecting even small details can have dire consequences. Each inspection should leave no doubt about safety.

Safe Operating Procedures and Techniques for Manual Hoisting

Manual hoisting is crucial in many industries. However, safety must always come first. According to a recent industry report, improper lifting techniques contribute to over 30% of workplace injuries. Following safe operating procedures is essential. Always check the hoisting equipment before use. Look for wear, damage, or any malfunctions. Failure to do so can lead to serious accidents.

Training is vital. Many workers underestimate the importance of proper lifting techniques. A study found that nearly 60% of employees had not received adequate training on manual hoisting. This lack of knowledge can lead to injury. Simple techniques can make a huge difference. For instance, workers should maintain a firm grip and use their legs to lift, not their backs. Encourage workers to communicate while lifting heavy items.

Regular safety drills can help build a culture of safety. Employees should know what to do in case of an emergency. However, many companies neglect this vital practice. It often leads to confusion during actual accidents. Establishing clear protocols and ensuring everyone understands them can greatly reduce risks. Remember, safety is not just about compliance—it's about cultivating awareness.

Related Posts

-

5 Essential Benefits of Choosing Air Hoists for Your Industrial Operations

-

Innovative Uses of Electric Chain Fall in Modern Industries

-

Maximize Your Exports with Manual Hoists at the Record Breaking Canton Fair 2025

-

Understanding the Importance of Industry Production Standards in Best Chain Fall Manufacturing

-

Unmatched Excellence in Crane Hoists Driving China's Export Strength to Global Markets

-

How to Maximize Safety and Efficiency with Lever Hoist in Industrial Applications

Copyright ©2024 Elephant Lifting Products | All rights reserved.

38381 N Robert Wilson Rd, Gonzales, LA 70737 USA

Toll Free: (888) 844-6113 | Phone: (225) 644-6113 | Fax: (225) 644-6695

Email: sale@floralift.org